In case of a multi stage well point system care should be taken that the header of the lowermost stage is not more than 4 m above the excavation bed so.

Well point dewatering system ppt.

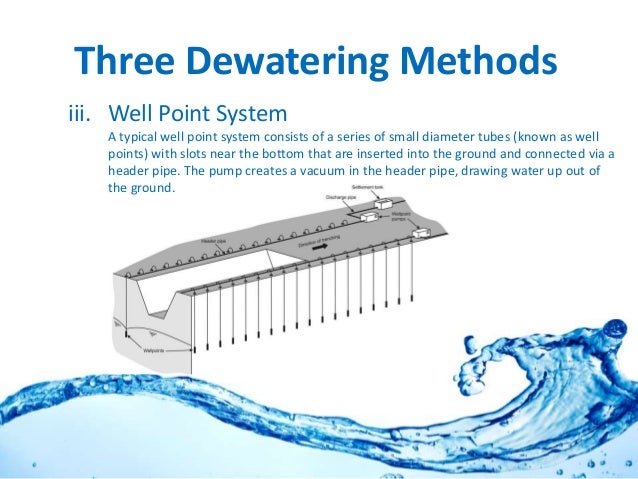

Well point systems a well point system consists of a number of well points spaced along a trench or around an excavation site all connected to a common header which is attached to one or more well point pumps.

Sometimes a single stage well point system is attached with jet eductor pump this system allows dewatering up to 25 to 30 m depth.

In case of a multi stage well point system care should be taken that the header of the lowermost stage is not more than 4 m above the excavation bed so.

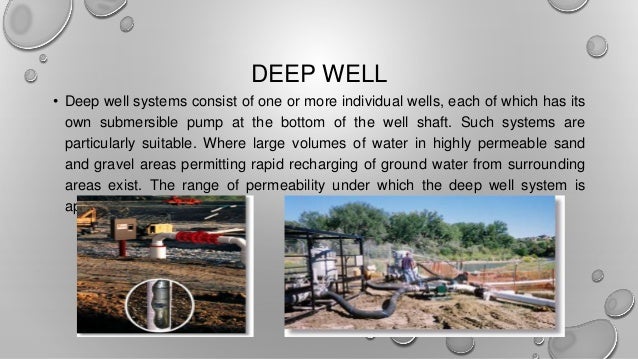

Wells are systematically drilled around the construction area and submersible pumps placed into these wells.

Sometimes a single stage well point system is attached with jet eductor pump this system allows dewatering up to 25 to 30 m depth.

For this high pressure of water make annular spacing around the well point.

When the well point is reached the required depth water forces is stopped.

A wellpoint dewatering system consists of a series of shallow wells known as wellpoints which are installed at a pre determined depth and appropriate spacing around an excavation.

These wellpoints are connected to a main pipe and are pumped out of the ground with a high efficiency water pump.

Additional stages can be installed if the excavation is deeper.

The wellpoints are connected to the surface via a riser pipe and in turn connected to a common header main pipe through a flexbow.

Then around the spacing of well point system.

Using jetting tubes and a water pump wellpoint dewatering is a fast and cost effective way to decrease water levels.

Well point is automatically inserted into the ground with the help of water pressure and without process of driving.

This is preferable over a multi stage well point system.

Wellpoint dewatering is widely used for excavations of shallow depths especially for pipeline trench excavations.

This is preferable over a multi stage well point system.

Well point assemblies made up of a well point screen riser pipe and swing joint with tuning are generally installed by jetting.

A sludge dewatering system like ours that extracts maximal liquid will therefore save space time and money as well as improving garbage conditions at the landfill.

Powerpoint ppt presentation free to view.

A properly installed system will pre drain and stabilize wet soils up to a depth of 17.

The system is economical and automated.

In appropriate ground conditions a wellpoint system can be installed speedily and made operational rapidly.

Can hand jet punch or pre drill.

This practice appears to work effectively for many projects especially those building projects that.

Our wellpoint dewatering system uses small diameter shallow wells that are evenly spaced.